Endress+Hauser Level+Pressure in Maulburg is a leading producer of instruments, sensors, components, and services for level measurement and level limit detection, pressure and differential pressure measurement as well as inventory management solutions.

At the Critical Chain 2023 conference, Dr. Dietmar Spanke, Head of the Project Management Office in Innovation Projects at Endress + Hauser Level+Pressure, shared how the research & development projects can benefit from implementing Critical Chain Project Management and Theory of Constraints.

Why Critical Chain Project Management (CCPM)

To start with, let’s understand the type of projects Endress+Hauser Level+Pressure is involved in. Essentially, they create measuring devices and their projects are either innovation or R&D projects. Developing products in R&D that combine hardware, firmware, and mechanics is inherently risky. The duration of the projects typically ranges from 6 to 36 months while project team size varies from 6 to 150 people.

As a result, Endress + Hauser experienced an average project deviation of 50% in 2014 which further resulted in a 50% increase in costs. Several projects were being started simultaneously but not as many were being completed, which led to the introduction of some measures to counter these challenges.

Implementation at Endress+Hauser

In 2015, Critical Chain Project Management was introduced as a global approach to achieving better performance. The objective was to have transparent and robust priorities, deal effectively with plan deviations and avoid harmful multi-tasking, meet deadlines, and deliver on time.

Keeping these factors in mind, Endress+Hauser shifted their focus from local to global optimum and took the following steps in implementing CCPM:

- New Project Management Software: Using LYNX enabled them to focus on the bottleneck of the system and ensure deadlines were met.

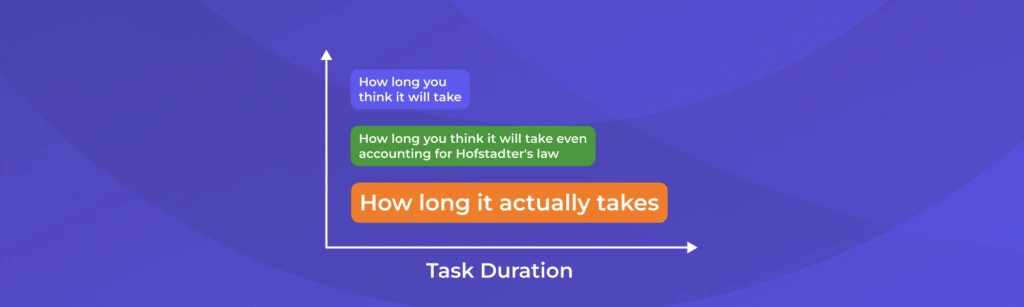

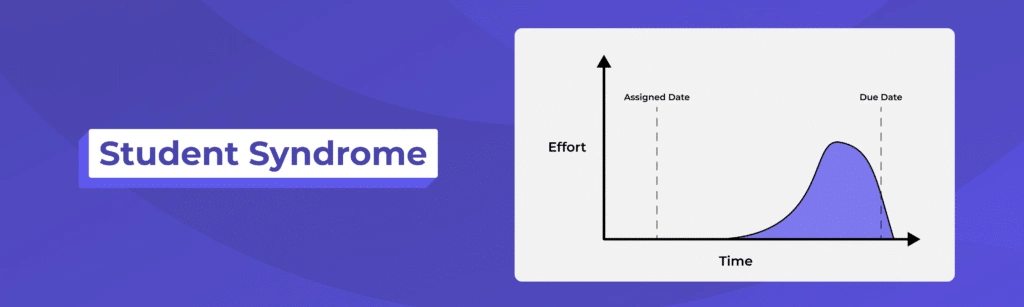

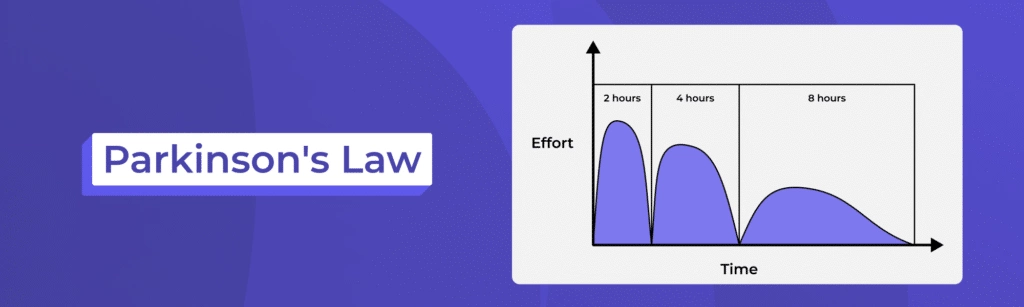

- Project Buffers: These were introduced to prevent parkinsons law and student syndrome

- Clear priorities: To prevent bad multitasking

- Active treatment of estimates: A task owner was put in place for each task who provided daily updates, enabling rapid response capabilities.

- WIP limitations in the portfolio: To create more room to maneuver projects, this helps projects that need support and focus on the overall portfolio.

- Control Loops: These were introduced to account for Murphy’s Law and other uncertainties.

The implementation was quickly done within the time span of a month. In addition to the above changes, there was also an important shift in the mindset required to accompany this implementation. This resulted in a new motto for the organization: “From my product to our portfolio with the flexibility to the best customer benefit”.

This further resulted in a change in how Endress+Hauser responds in crisis situations, with a new focus on what can be done to achieve the common goal of the organization and provide support where required.

Results and Benefits

Since then, more than 120 projects have been completed and it has become clear that the implementation of CCPM and LYNX has been a resounding success for Endress+Hauser. Here is a brief overview of the results:

- Project delays were reduced by 50%

- The number of completed projects doubled

Conclusion

To conclude, it can be safely stated that the implementation of CCPM for the R&D projects of Endress+Hauser was successful. While there is still room for improvement and learning as Dr. Dietmar Spanke notes, using CCPM and software such as LYNX helps identify these challenges at an early stage and make the best decisions for the portfolio.

This article shared insights from a session by Dr. Dietmar Spanke at the Critical Chain 2023 Conference by TOCICO. If you would like to know more, watch the video recording of the session on the TOCICO website (login required) here.