The LYNX software by A-dato is not only a tool for project portfolio management, but also a highly sophisticated resource management solution. One of the reasons it is so effective at resource management is its compliance with the ISA-95 Resource Management Model. In this article, we will explore the following:

- What is the ISA-95 model?

- The importance of effective resource management

- ISA-95 model in LYNX

What is the ISA-95 model?

The International Society of Automation (ISA) developed ISA-95, which is also known as ANSI/ISA-95 as an international standard for manufacturers across the globe and industries. Harjunkoski and Bauer (2014) define it in the following way:

“ISA-95 is the international standard for the integration of enterprise and control systems. ISA-95 consists of models and terminology that can be used to determine which information has to be exchanged between systems for sales, finance, and logistics, and systems for production, maintenance, and quality.”

From this definition, we can infer that the standard has a variety of applications, including the scheduling of projects and resource management.

Effective Resource Management

Resource management is a critical component of effective industrial operations, encompassing the efficient and effective deployment and allocation of an organization’s resources when and where they are needed. These resources can range from tangible assets like machinery and materials to intangible assets such as human skills and information technology.

Challenges in Resource Management

Despite its importance, resource management comes with its set of challenges. One of the primary challenges is the variability and unpredictability in demand, which can lead to either resource shortages or surpluses (Barney, 2001). Balancing the scale to meet demand without overcommitting resources is a delicate act. Moreover, the complexity of modern industrial operations, with intricate supply chains and interdependencies, adds another layer of difficulty in resource planning and allocation.

Another significant challenge is the integration of various types of resources. In many cases, information systems, machinery, and human resources operate in silos, leading to inefficiencies and communication gaps. Ensuring that these diverse resource types work in harmony is a critical aspect of effective resource management (Brown et al., 2005).

Impact on Productivity and Efficiency

The strategic management of resources directly impacts an organization’s productivity and operational efficiency. Efficient resource management leads to shorter production cycles, lower inventory costs, and improved quality of products or services. It also enhances an organization’s ability to respond swiftly to market changes and customer demands, thereby providing a competitive edge in the industry (Spearman & Hopp, 1990).

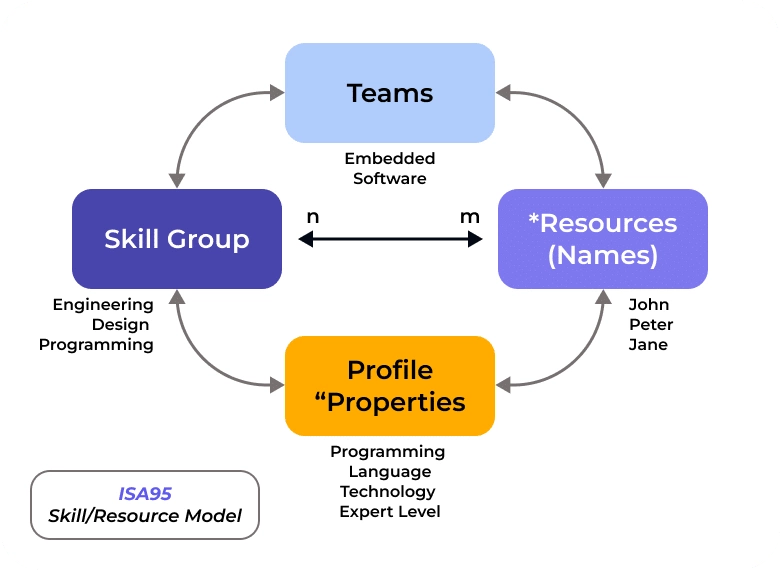

ISA-95 model in LYNX

LYNX underscores the critical role that skills, resources, and profiles play in the process of allocating resources, in line with the ISA-95 Resource Management Model. By organizing skills within LYNX, it becomes possible to systematically assign tasks to the most suitable team members, ensuring efficiency and effectiveness in task execution. Resources, which include everything from machinery to physical spaces, can be meticulously managed within LYNX. This comprehensive management aids in avoiding any operational delays and guarantees the seamless progression of projects. Furthermore, profiles act as the framework for aligning skills with the necessary resources. Through LYNX, you can create and tailor these profiles, thereby enhancing the accuracy and efficacy of the resource allocation mechanism.

In conclusion, harnessing ISA95 within LYNX for resource management offers a structured approach to optimize operations. By effectively categorizing skills, efficiently managing resources, and precisely defining profiles, businesses can ensure seamless project execution and significantly improve productivity, paving the way for enhanced operational success.

References

- Barney, J. B. (2001). The theory and practice of resource-based strategy in a new economy. European Management Journal, 19(6), 572-580.

- Brown, S., Lamming, R., Bessant, J., & Jones, P. (2005). Strategic Operations Management. Elsevier.

- Harjunkoski, I., & Bauer, R. (2014). Sharing data for production scheduling using the ISA-95 standard. Frontiers in Energy Research, 2. https://doi.org/10.3389/fenrg.2014.00044

- Kumar, S. A., & Suresh, N. (2009). Production and Operations Management. New Age International.

- Schneeweiss, C. (2005). Resource Management in Manufacturing Systems: Optimization Algorithms for Production Planning. Springer.

- Spearman, M. L., & Hopp, W. J. (1990). Industrial and operations management: Integrating manufacturing and services. Journal of Manufacturing and Operations Management, 3(3), 269-288.