Bring Focus & Performance

into your Project Portfolio.

Generate Real-time Work Priorities | Eliminate Bottlenecks | Finish More, Faster | Improve Throughput | End-to-End Project & Portfolio Management

A Solution for Every Role

Tailored to meet your organization’s diverse needs, LYNX software provides specialized solutions for multiple roles, empowering each with a unified platform.

They Make Work Flow.

You Can Too.

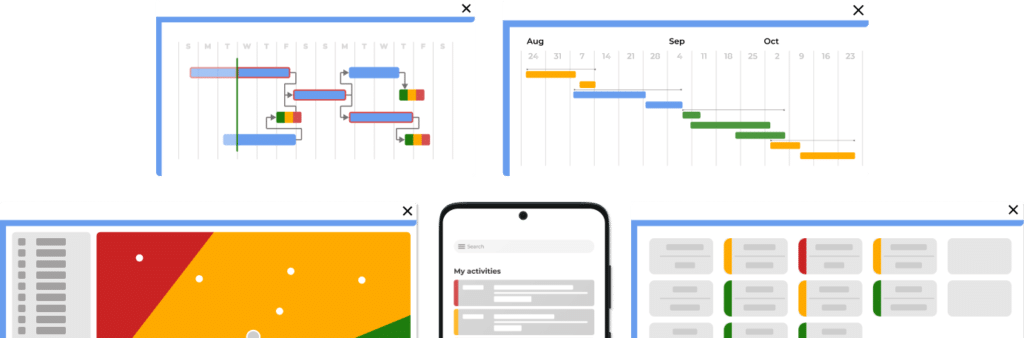

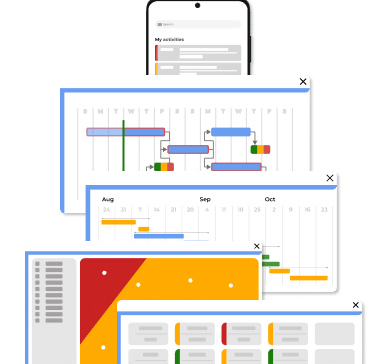

A Complete CCPM Software

Your projects needs more than Critical Path. Unleash the power of true end-to-end Critical Chain Project Management (CCPM) integration with LYNX software.

and Mitigate Risks

LYNX software employs advanced analytics for pinpointing bottlenecks and proactively mitigates risks, ensuring seamless project progression.

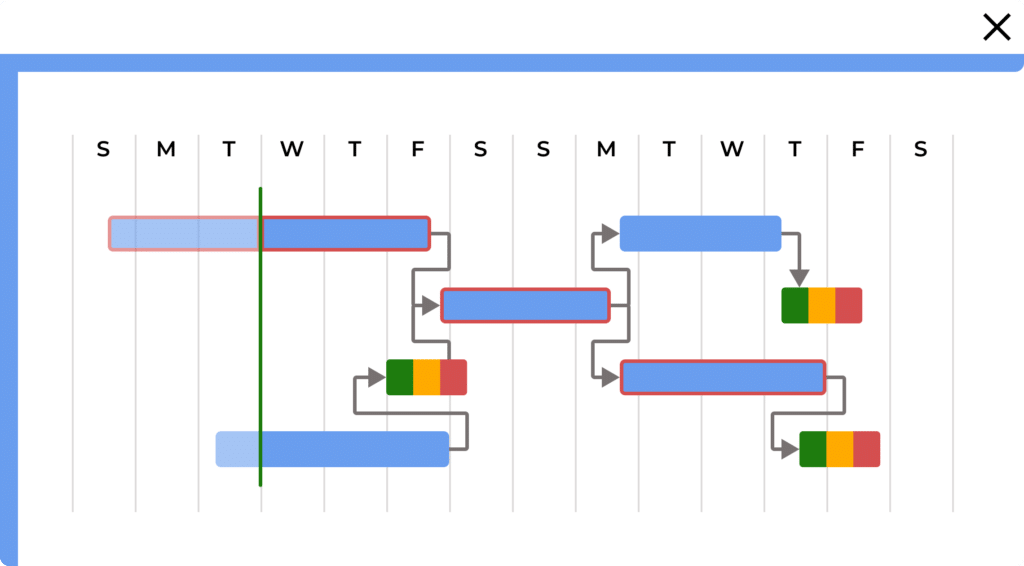

Feeding Buffers

LYNX software optimizes project timelines by strategically implementing critical and feeding buffers, ensuring robust project execution, and timely delivery.

Match your Needs

There’s no one-size-fits-all CCPM application. LYNX software is configurable to match your unique needs, providing an experience tailored to your organization’s requirements.

Success Stories

“The beauty of working with A-dato is that we can have a unity of purpose on each level within the company.”

Bo Burgmans

Managing Director, Bruns B.V.

“This is more successful than anything we have ever wanted from this change process.”

Dr. Peter Selders

CEO, Endress + Hauser

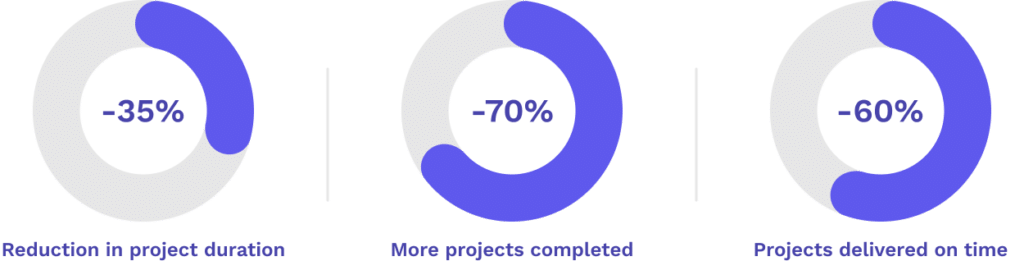

An Enterprise-Ready Solution

Real Project, Real Results.

*Figures are results achieved on average.

LYNX Software brings together CCPM, TOC, Agile, Scrum, Kanban, and Lean Essential Flow into one integrated solution.